Class II Dielectric (Radial Commercial Chip X7R)

*RoHS Compliant if requested

The following table represents our standard listing of MLC’s produced from our stable EIA Class II X7R dielectric. In addition to the below listed standard case sizes, WCI is ideally situated to custom fabricate alternative size, thickness and/or voltage ratings per individual requirements. Should you not find what you are looking for please call the factory.

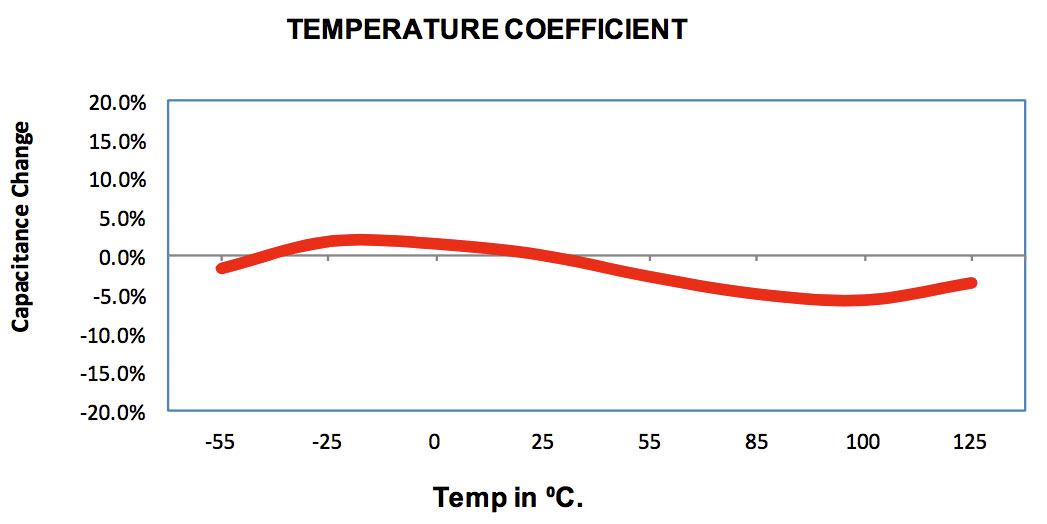

Class II X7R capacitors are very well suited to applications allowing for predictable changes in electrical properties given time, temperature and voltage. A temperature coefficient of ±15% is standard and typical results are detailed below. Common applications include aerospace, defense, pulse energy detonation and higher end consumer needs requiring a greater degree of safety/reliability.

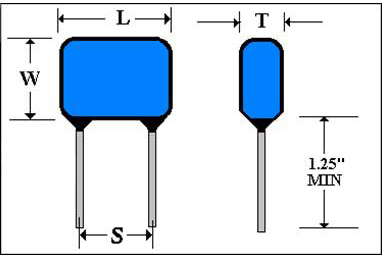

Case Sizes (in inches)

|

|

|

|

|

|

|

|

|

| SIZE | 1210 | 1515 | 1812 | 1825 | 2020 | 2225 | 2520 | 3530 |

| LENGTH-NOM | 0.220 | 0.270 | 0.300 | 0.300 | 0.320 | 0.350 | 0.400 | 0.470 |

| WIDTH-NOM | 0.200 | 0.250 | 0.220 | 0.350 | 0.300 | 0.350 | 0.300 | 0.400 |

| THICK-MAX | 0.200 | 0.250 | 0.300 | 0.300 | 0.350 | 0.350 | 0.350 | 0.350 |

| LEAD SPACING | 0.140 | 0.170 | 0.200 | 0.200 | 0.220 | 0.245 | 0.275 | 0.375 |

| SIZE | 4040 | 4540 | 5550 | 6560 | 7565 | 8840 | 11050 | 13060 |

| LENGTH-NOM | 0.520 | 0.570 | 0.670 | 0.770 | 0.870 | 1.000 | 1.220 | 1.420 |

| WIDTH-NOM | 0.500 | 0.500 | 0.600 | 0.720 | 0.770 | 0.500 | 0.600 | 0.720 |

| THICK-MAX | 0.400 | 0.400 | 0.400 | 0.400 | 0.400 | 0.400 | 0.400 | 0.400 |

| LEAD SPACING | 0.425 | 0.475 | 0.575 | 0.675 | 0.775 | 0.900 | 1.125 | 1.325 |

Dimensions are maximums

Note: These are standard sizes. We can manufacture any size required. Please consult factory for special builds.

Max Capacitance Table*

| SIZE | 1210 | 1515 | 1812 | 1825 | 2020 | 2225 | 2520 | 3530 |

| 250V | 473 | 104 | 104 | 224 | 154 | 274 | 154 | |

| 500V | 223 | 563 | 563 | 154 | 104 | 184 | 124 | 394 |

| 1000V | 562 | 183 | 183 | 563 | 473 | 823 | 563 | 184 |

| 2000V | 102 | 392 | 392 | 153 | 123 | 183 | 153 | 473 |

| 3000V | 152 | 152 | 392 | 332 | 472 | 392 | 183 | |

| 4000V | 152 | 562 | ||||||

| 5000V | 102 | 472 | ||||||

| 7000V | 182 | |||||||

| 10000V |

| SIZE | 4040 | 4540 | 5550 | 6560 | 7565 | 8840 | 11050 | 13060 |

| 250V | ||||||||

| 500V | 474 | 564 | ||||||

| 1000V | 274 | 334 | 474 | 105 | 105 | |||

| 2000V | 683 | 823 | 154 | 224 | 274 | |||

| 3000V | 223 | 223 | 473 | 823 | 104 | |||

| 4000V | 822 | 103 | 223 | 333 | 393 | 183 | 473 | 563 |

| 5000V | 392 | 562 | 822 | 153 | 183 | 822 | 223 | 223 |

| 7000V | 122 | 472 | 562 | 103 | 682 | 562 | 153 | 183 |

| 10000V | 102 | 122 | 222 | 392 | 392 | 332 | 562 | 822 |

*Note: Maximum capacitance values are shown above as 3 digit code: 2 significant figures followed by the no. of zeros e.g. 153 = 15,000pF. R denotes decimal e.g. 1R5 = 1.5pF

Temperature Coefficient

X7R (X)

| Material: | X7R (BX) |

| Temperature Coefficient: | ±15% |

| Voltage Coefficient: | -25% Max. |

| Operation Temperature Range: | -55°C to 125°C. |

| Dissipation Factor: | 2.5% max at 25°C. |

| Insulation Resistance: |

at 25°C > 100GΩ or 1000MΩμF or whichever is less. at 125°C > 10GΩ or 100MΩμF or whichever is less. |

| Dielectric withstanding Voltage: |

250% for parts ≤250V. 150% for parts 250V-1KV. 120% for parts >1KV. |

| Aging Rate: | <2% per decade. |

| Testing Parameters: |

1kHz, 1.0 ± 0.2VRMS, 25°C. 1mHz for capacitance ≤ 100pF. |

Ordering Information

| Prefix | Case Size | Encapsulation | Dielectric | Capacitance | Tolerance | Termination | Voltage | Suffix |

| WC | 3530 | C | X | 103 | K | D | 302 | |

|

WC - Standard WCN - Non Standard WCR - RoHS |

Chip Size |

Blank = Chip C = Conformal Coating E = E Lead G = Gull Lead J = J Lead L = L Lead T = Tab Lead |

N = NPO X = X7R See Dielectric Characteristics for full list |

Capacitance Value Code in pF 1st two digits significant, 3rd the power of ten i.e.: 102 = 1000pF |

F = ±1% G = ±2% J = ±5% K = ±10% M = ±20% Z = +80%/-20% V = +100% |

A = Ag D = PdAg |

Voltage Code 1st two digits significant, 3rd the power of ten i.e. 102 = 1000V |

-NM = No Marking -X### = Special Thickness |

Dielectric Codes

| Dielectric Code | Material |

Temperature Coefficient Please see Dielectric Characteristics for more information |

| N | COG/NPO | -55°/+125°C |

| R | N2T | -55°/+125°C/ ±500pm |

| B | X7R/BR | BR -55°/+125°C |

| X | BX/MIL | BX -55°/+125°C VC -25% max |

| Y | Y5V | Y5V -30°/+85°C |

Prefixes

| Prefix | Description |

| WC | Standard |

| WCN |

Non standard Requirements High Temperature High Reliability |

| WCR | RoHS Compliant |

| HT | High Temperature (Potted Units) |

| HTN | High Temp w/ High Reliability Testing (Potted Units) |

| SM | Surface Mount |

| SMN | Surface Mount with High Reliability Testing |

Capacitance Tolerance Codes

| Code | Tolerance |

| F | ± 1% |

| G | ± 2% |

| J | ± 5% |

| K | ± 10% |

| M | ± 20% |

| Z | +80%/-20% |

| V | + 100% |

Suffixes

| Suffix | Description |

| -NM | No Marking |

| -NC | No Coating |

| -X### | Special Thickness |